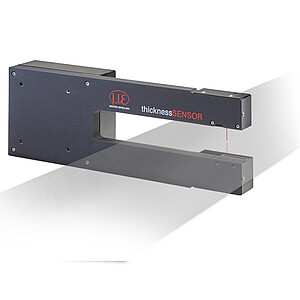

Central marking line - CML

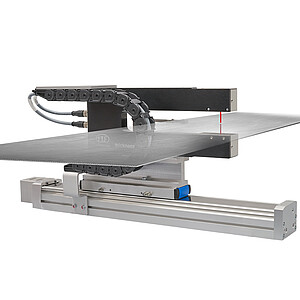

The CML central marking line increases the efficiency of the marking process in final production. Less effective marking stations installed as part of the tire uniformity line and the balancing line are replaced by central marking modules where all markings are applied in one station, significantly increasing the efficiency of the marking head usage. The CML marking line is also suitable for applying a second marking. In cases where an additional marking is required and the marking stations in the tire uniformity line or the balancing line are not capable or available, the second marking can be placed in the central marking line.

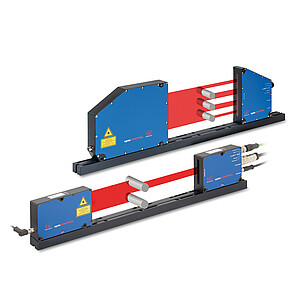

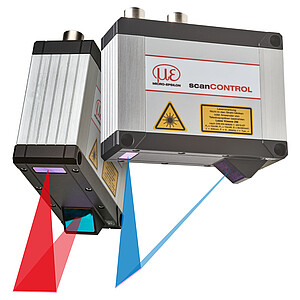

The marking process is determined by the position of the barcode or the existing mark as a reference point for the second or next mark. This spotting functionality is provided in the spotting station, which is typically used to obtain the correct position of the first mark based on the barcode or the position for the second mark based on the existing mark. To request the next mark, the marking module also includes a spotting function that makes it possible to define the next angle for the mark, regardless of whether the mark is applied to the lower or upper side wall.

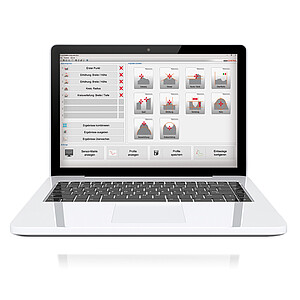

The entire marking process is fully controlled by a PLC based on information from the customer's factory network, including parameters such as temperature, marking time and marking pressure. The CML marking line can also be equipped with a camera to check the quality of the marking in the marking area. The central marking inspection system can be utilized for quality inspection of the entire upper and lower sidewall. The web-based software, which can be accessed directly at the machine or via the factory network on a cell phone or tablet, includes an online monitoring system, a complete results database and a predictive maintenance module.