Retrofit TU machines - precision by masking unwanted effects

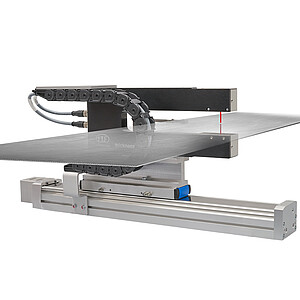

One of the most cost-effective ways to increase production is to retrofit an existing system with a new control unit and a comprehensive interface to the measuring system.

Precision by eliminating unwanted effects

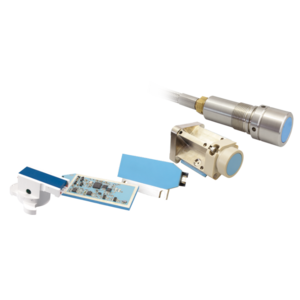

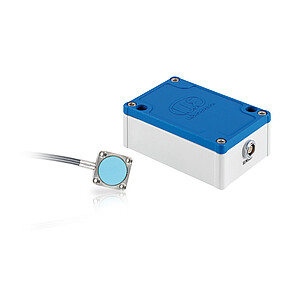

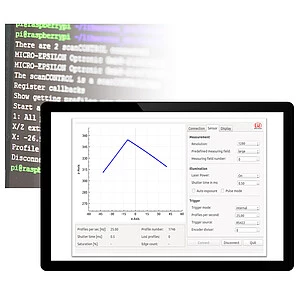

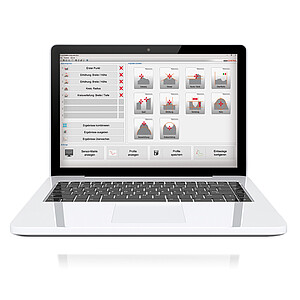

The restructuring of TU systems includes the replacement of electrical and pneumatic components as well as the measuring system for recording tensiometric forces. An efficient control system ensures the reliability of the entire system. Communication with other parts such as conveyor systems, control systems and data acquisition is also handled by the renewed systems.

The measuring system detects radial and lateral forces - absolute values, peak-to-peak values, harmonic analysis, conicity, plysteer - and is calibrated using certified ballasts.

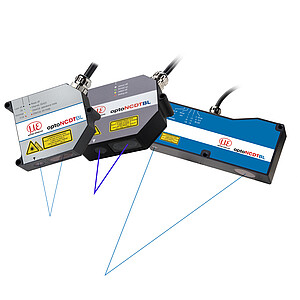

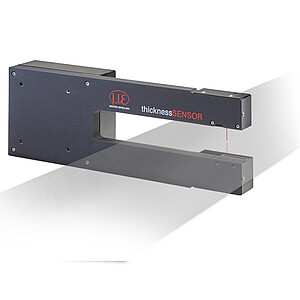

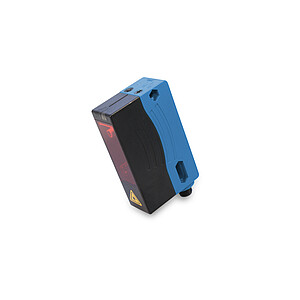

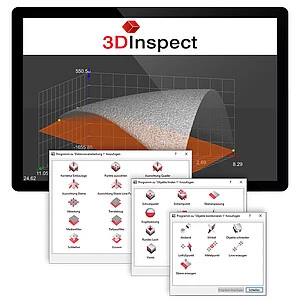

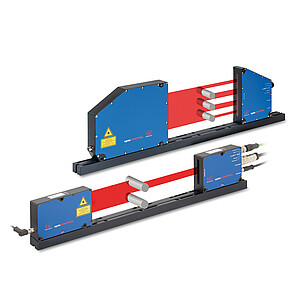

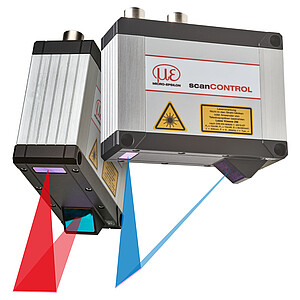

In addition, the TGI 8302.PLT/T detects the size of imperfections (dents, neckdowns) and evaluates the radial and lateral axial runout using laser line scanners.