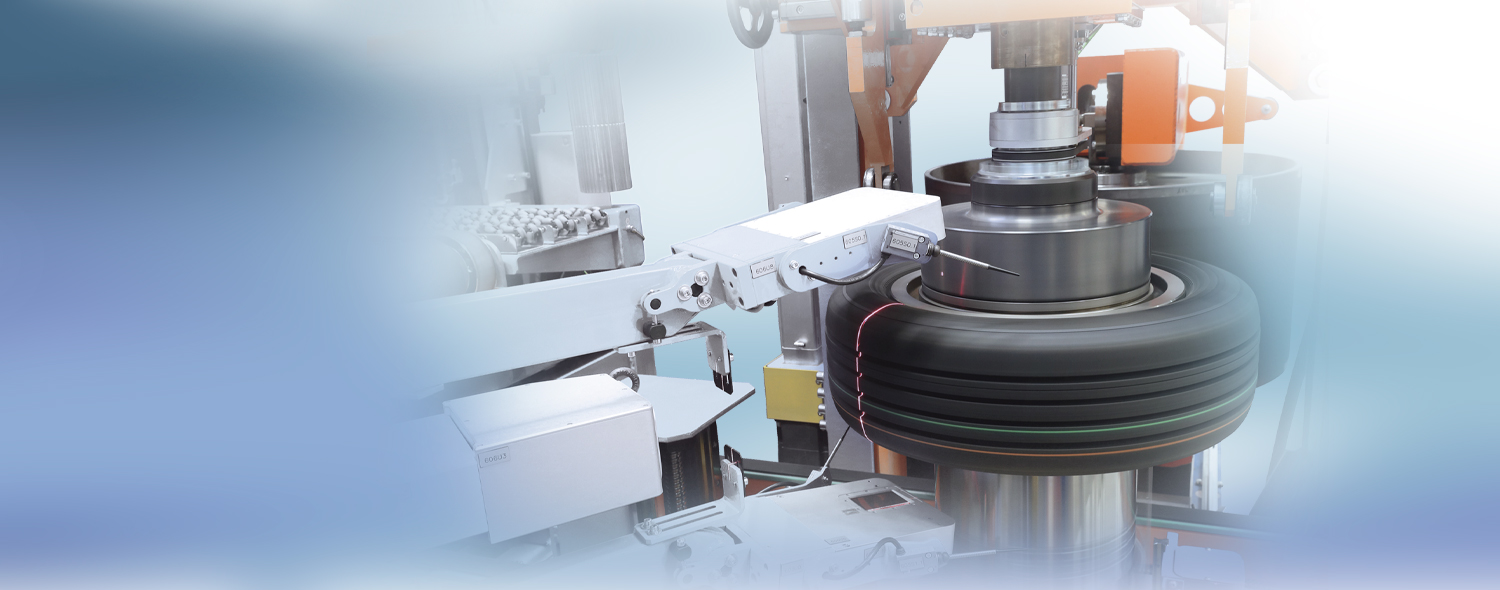

Tire geometry inspection

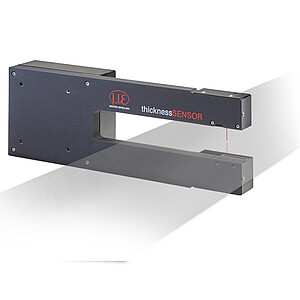

The dimensionCONTROL 8302.PLT/TT series makes a significant contribution to quality assurance during tire production by precisely checking radial and axial runout and inspecting the sidewalls for dents and constrictions.

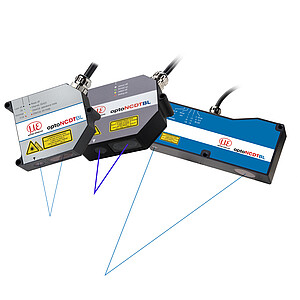

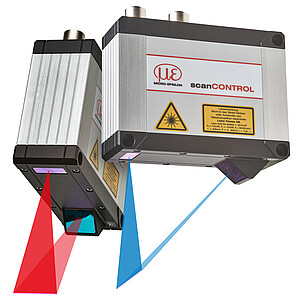

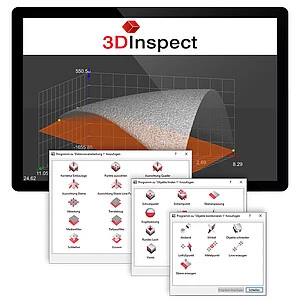

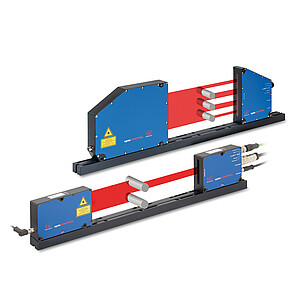

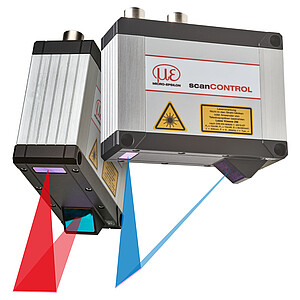

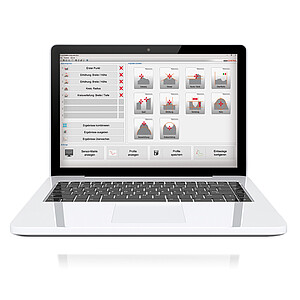

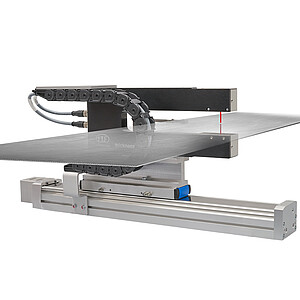

The dimensionCONTROL TGI 8302.PLT/TT uses special laser line scanners mounted on a solid precision frame to enable optimum reading of sidewalls and patterns. The system measures the size of the defects (dents, neckings) and evaluates the concentricity and axial runout. The system combines displacement data with angular positions recorded by an encoder to generate a partial 3D model of the outer skin. It hides embossing, records the position of defects and provides information on their size. During the axial runout measurement, the system creates a harmonic analysis and applies various filters to suppress the high-frequency noise. The mechanical basis of the dimensionCONTROL TGI 8302.PLT/TT is a C-frame arrangement in which the upper and lower belt sensors and the tread sensor are adjusted fully automatically to the respective tire size by traversing units. The actuators can be alternatively operated by servo or stepper motors. The controlling parameters can be written in a database.

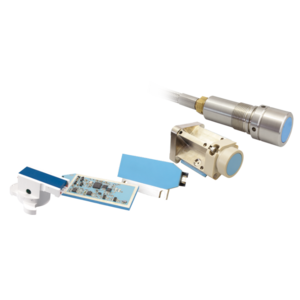

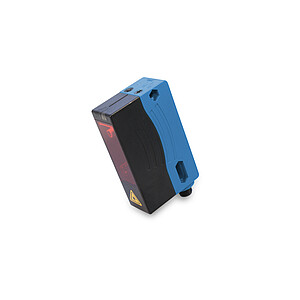

By using laser line scanners that are optimized for use in tire geometry measuring systems, the systems are also suitable for use in older TU machines. Due to the special arrangement of the optics, they have a superior ratio of line length and measuring range to installation space.