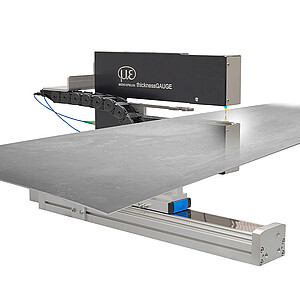

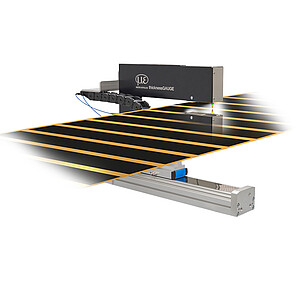

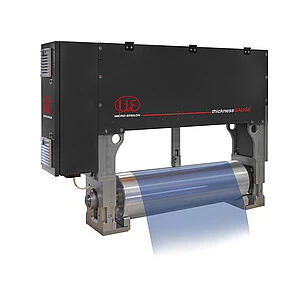

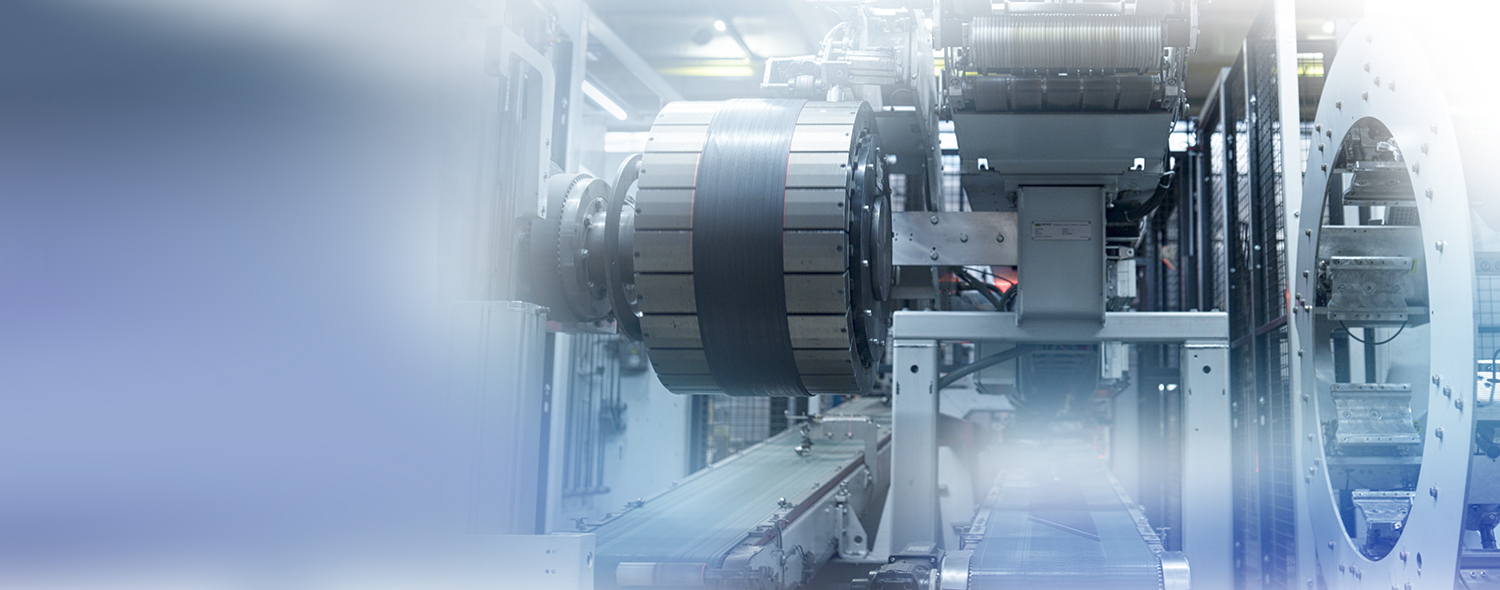

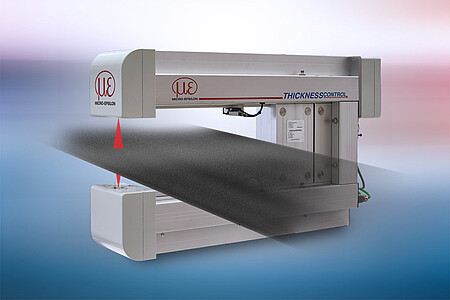

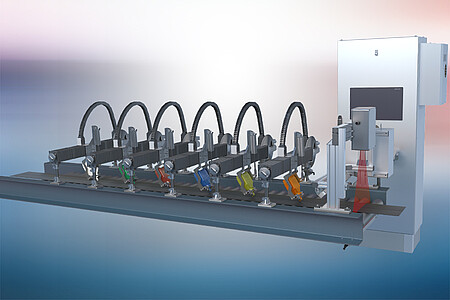

Measuring and inspection systems for the preparation area

The early detection of process errors in the manufacture of tire components is crucial for optimizing production costs. Micro-Epsilon system technology considerably reduces material waste and increases the quality of semi-products, which is a decisive factor for the outstanding quality of the final product - the tire.

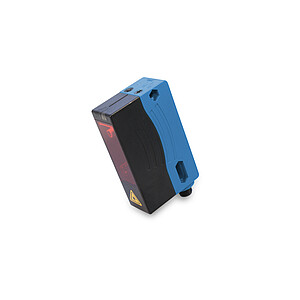

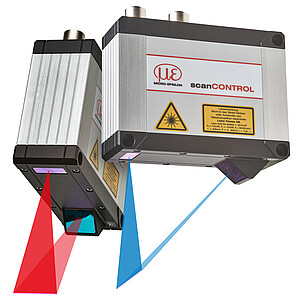

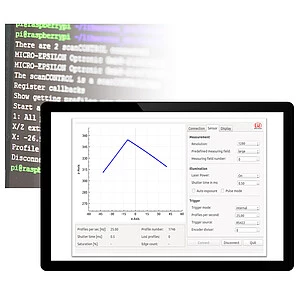

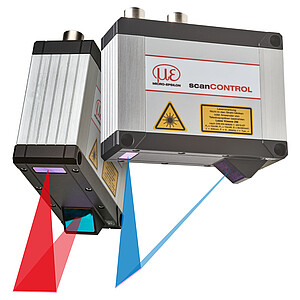

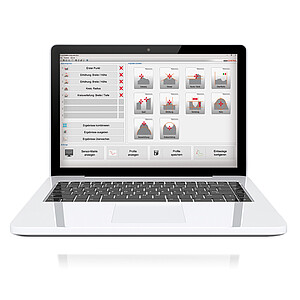

To achieve the stated goals, Micro-Epsilon has developed systems that are perfectly tailored the to challenges of the tire components production. They are designed to cope with fluctuating temperatures of more than 10 °C, vibrations, dust and chemical substances which allows for the systems to ensure precise measurement results even under challenging conditions.

An integral part of our systems is the comprehensive testing of each measuring system. In addition to functional testing, the behavior of the systems under changing ambient temperatures is analyzed, which is the key for long-term stability and reliability of the measuring systems.

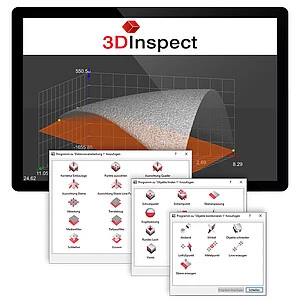

Our solutions set new benchmarks in tire production and help to considerably improve the quality and efficiency of your processes.

Fields of application

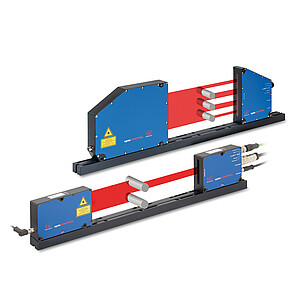

- Profilometer for tire components

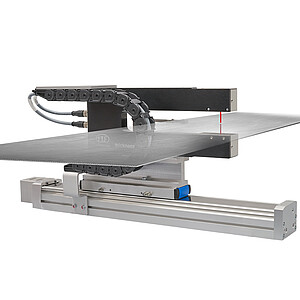

- Offline profilometer for tire components

- Color code inspection

- Tire width inspection

- Tire weight measurement

- Tread weight measurement

- Tread length measurement