Tire component profilometer - additional inspection

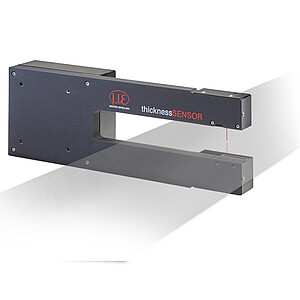

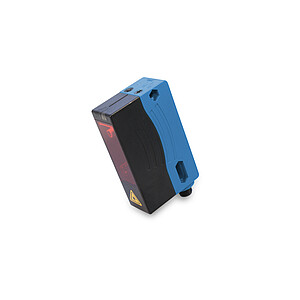

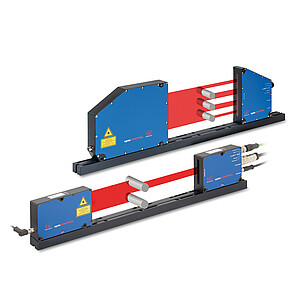

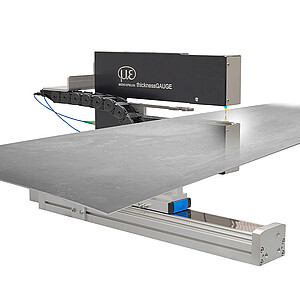

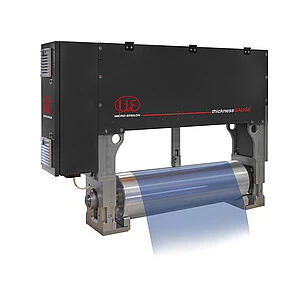

The non-traversing profilometers of the thicknessCONTROL TCP 8301.I series impress with their ability to measure complete profiles with high precision. These systems operate with virtually no moving parts and offer a solution with minimal maintenance requirements.

Additional inspection

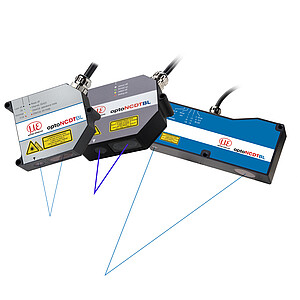

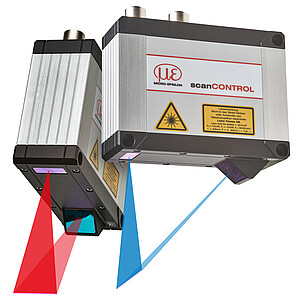

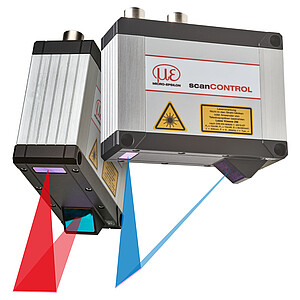

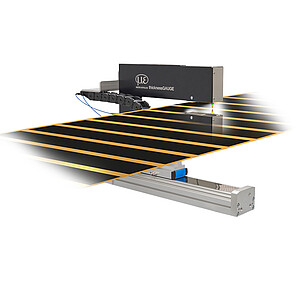

Based on the principle of optical triangulation, two parallel laser lines are projected onto the top and bottom of the material. The reflection of the laser light is detected by cameras. The measuring system has an integrated auto-calibration function. The patented calibration process typically takes approx. 5 minutes.

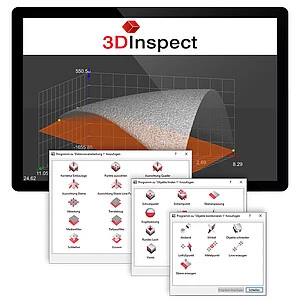

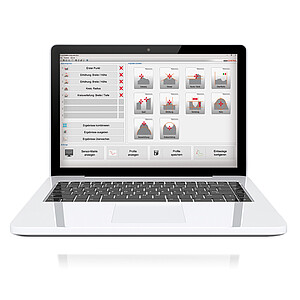

The profilometer visualization software includes tools for statistical processing and for outputting the measurement results in various formats. The measuring system is completely covered which minimizes the impact of ambient light unwanted reflections.

Additional inspection

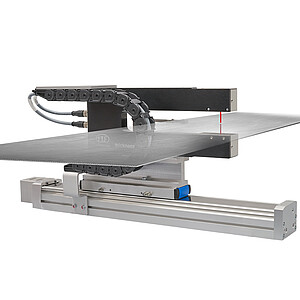

Thanks to the option of integrating the dimensionCONTROL TLI 8303.I length inspection system and the dimensionCONTROL TPWI 8302.LC width measuring device, the profilometer provides an efficient basis for the overall quality control of an extrusion line.