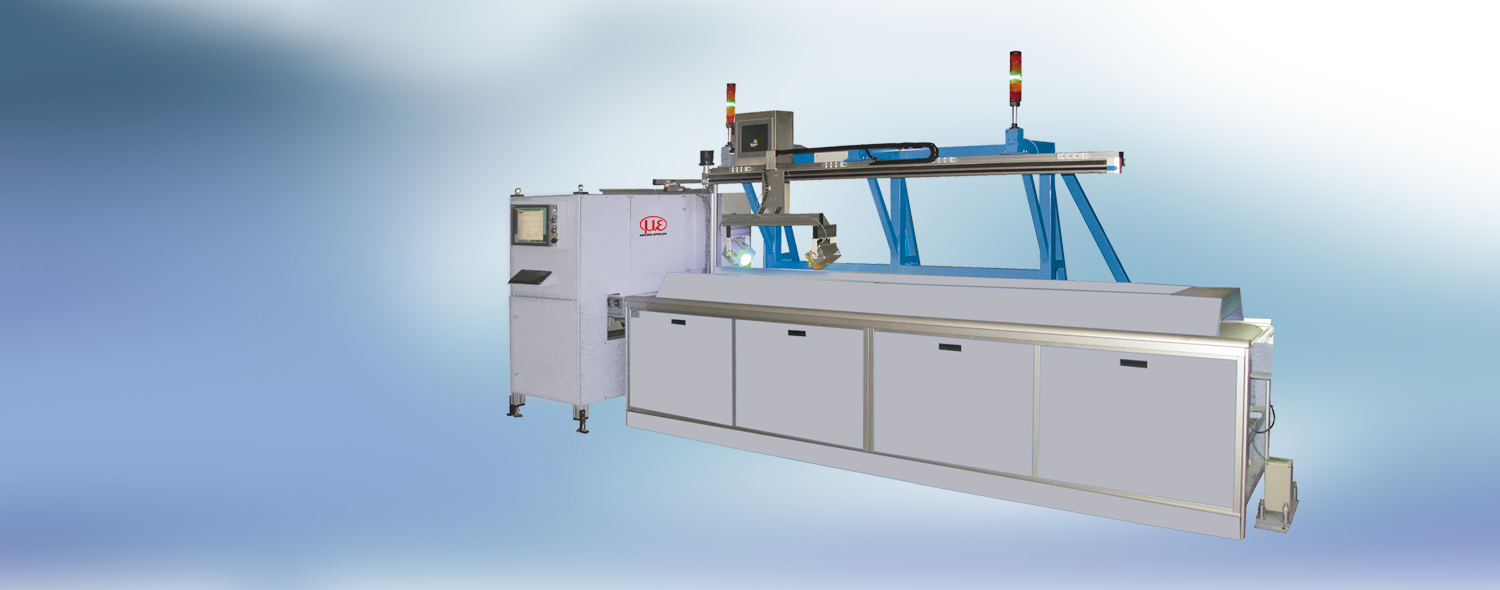

Tire length inspection - Optimized process imaging

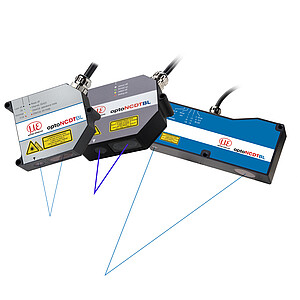

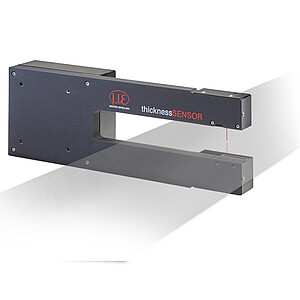

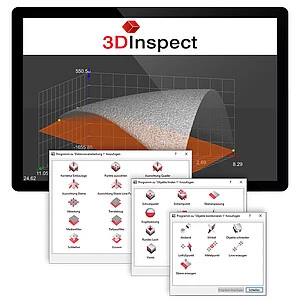

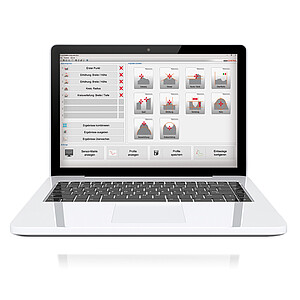

The dimensionCONTROL TLI 8303.I length measuring system is characterized by highly efficient image processing algorithms that also calculate the subsequent accuracy of fit of the strips in the tire building machine.

Optimized process imaging

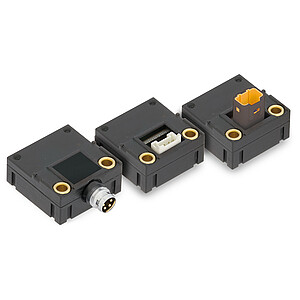

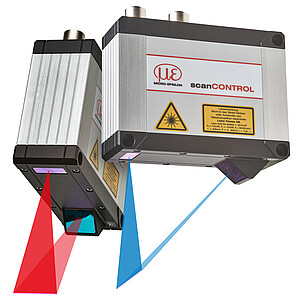

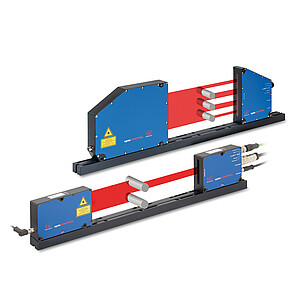

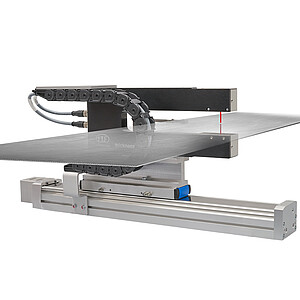

The integrated image processing system comprises two cameras for profile length inspection in extrusion lines. The first camera is installed on an electrically driven axis that can be positioned according to the recipe at the start of the profile, the second at the end of the profile. Depending on the version, the camera is positioned either under the roller conveyor at the end of the scale or above the scale. The moving camera is positioned according to the nominal length transmitted by the guidance system so that the two cut edges can be captured together in the focus of the cameras. The calculation of the profile length is based on the shape of the cuts at each edge. In order to optimize the imaging of the inspection result and the profile fit in the tire building machine, the edges are virtually connected to each other in accordance with the scanned surface. Based on these values and the position between the cameras, the final length is calculated.