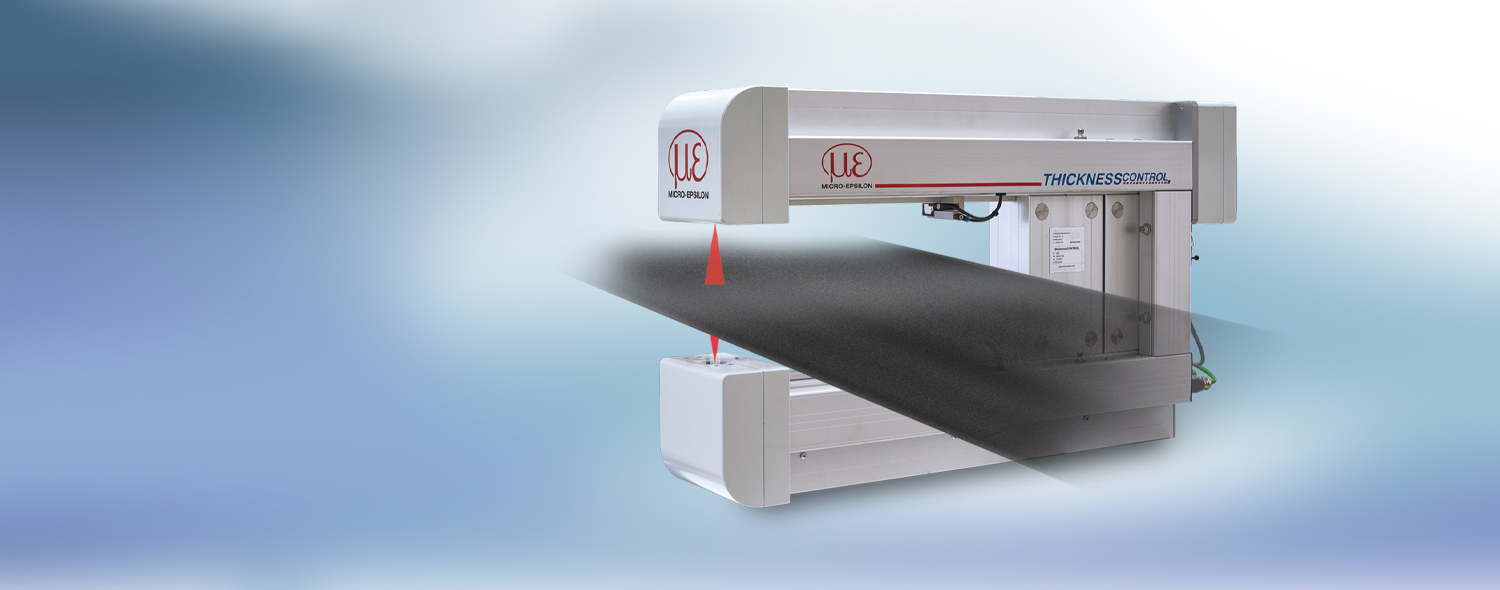

Profilometer for tire components - High data volume

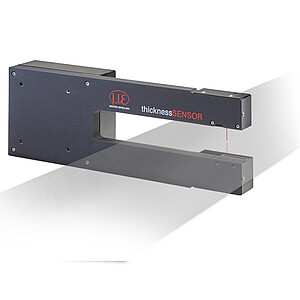

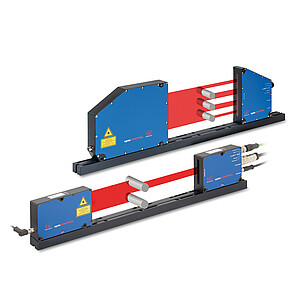

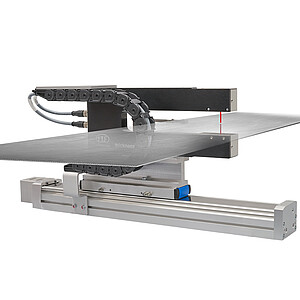

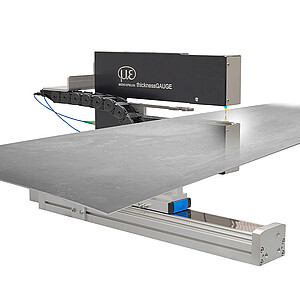

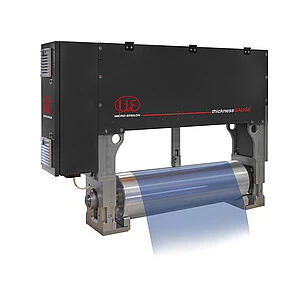

The modular and robust C-frame systems of the thicknessCONTROL TCP 8302 series impress with their long-term flexibility and high performance. Their compact design enables the integration of precise testing technology even in systems with limited installation space.

High data volume

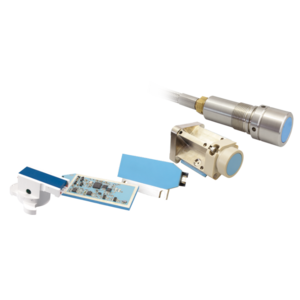

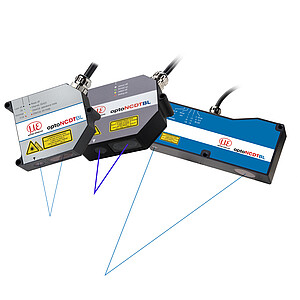

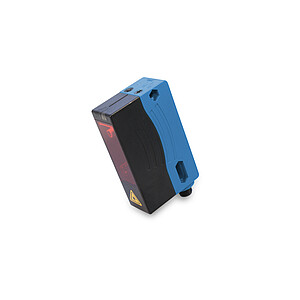

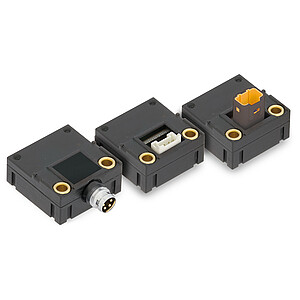

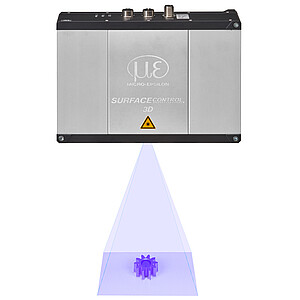

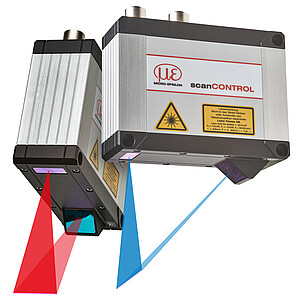

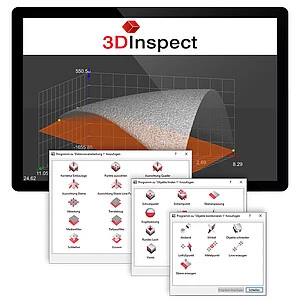

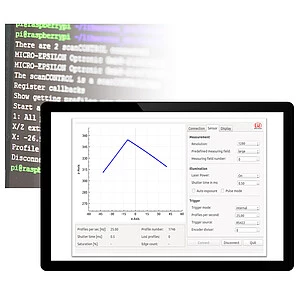

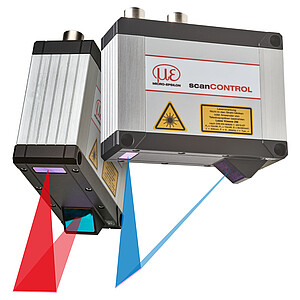

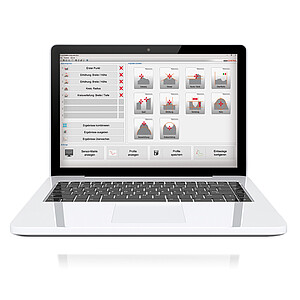

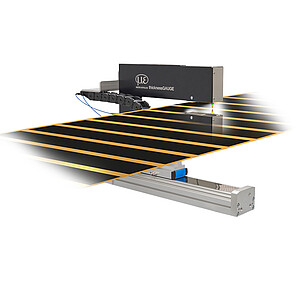

In the upper and lower belts of the C-frame, either laser triangulation point (ILD) or laser triangulation line (LLT) sensors are integrated. The thickness profile of the material to be measured is calculated from the difference between the sum of the sensor signals and the calibrated working gap. In combination with highly-efficient signal processing algorithms of the analysis and visualization software, accuracies in the micrometer range are achieved. A fully-automatic in-situ calibration makes the measurement resistant to temperature influences, i.e. the system can be installed even in harsh industrial environments and maintain the highest inline precision. The non-contact sensor technologies are wear-free and do not use isotopes or X-rays. Using optical technology provides long-term reliable measurement data while avoiding consequential costs.

With integrated laser line sensors that generate a high data volume of 128,000 data points per second, thicknessCONTROL TCP 8302.LLT offers a unique range of solutions for profile thickness measurement applications in the rubber processing industry.