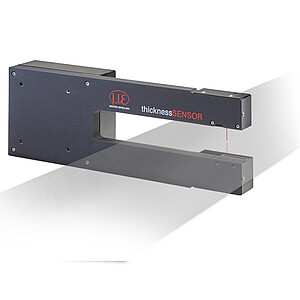

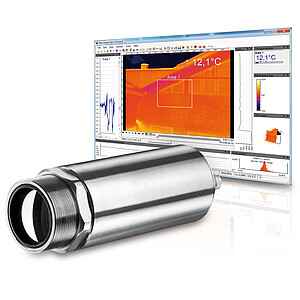

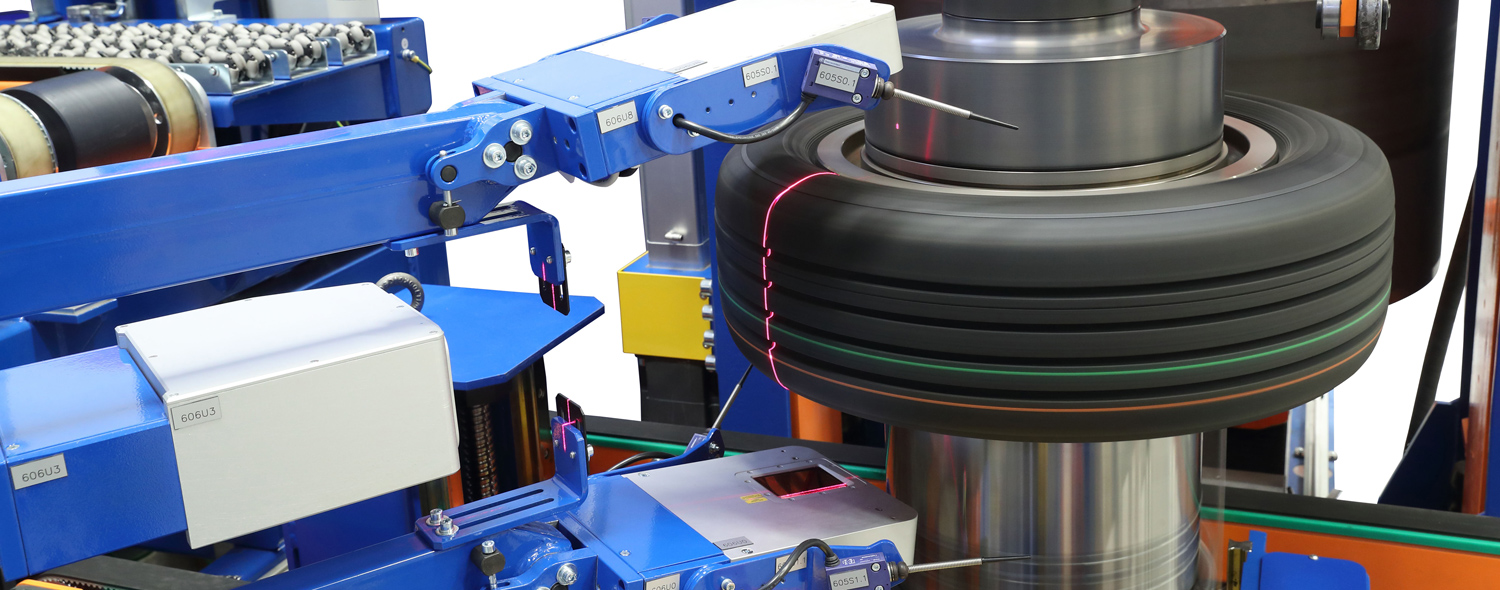

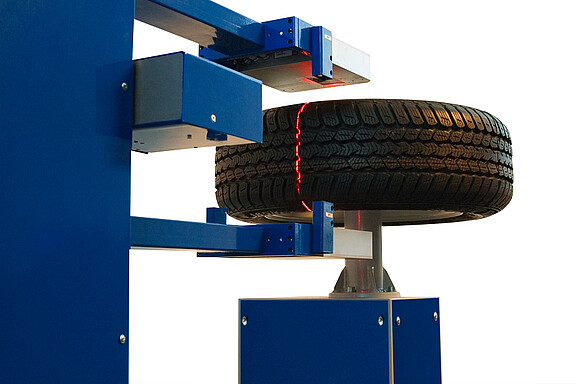

Tire geometry inline inspection in TU machines

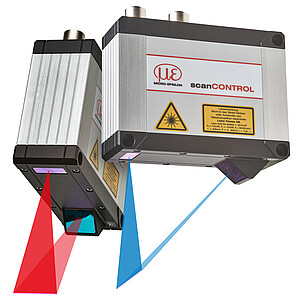

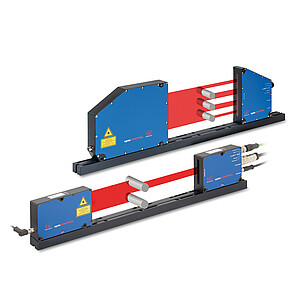

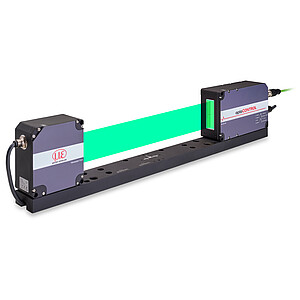

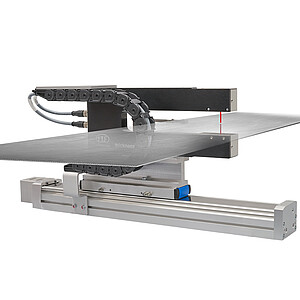

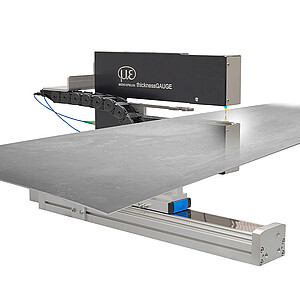

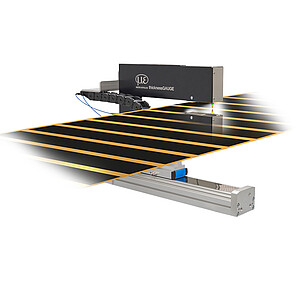

Monitoring tire geometry i.e. the measurement of radial or lateral unbalance as well as side wall detection for bulges, constrictions, dents etc., is one of the most important inspections at the end of the production process. The TGI 8302.LLT system can be easily integrated while offering precise measuring results.

Benefits:

- Suitable for all common TU machines and therefore ideal for retrofit

- Optical measuring principle

- Total surface scan

- Reduced pseudo-error rate

- Robust, low-vibration construction

Material parameters:

- Tire width from 100mm to 460mm

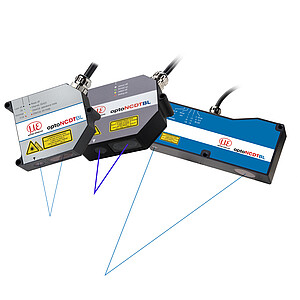

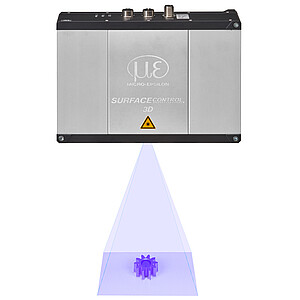

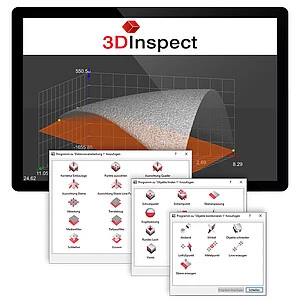

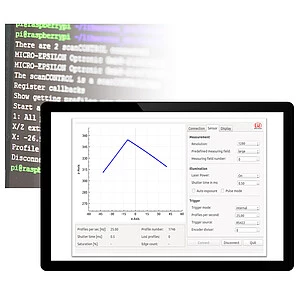

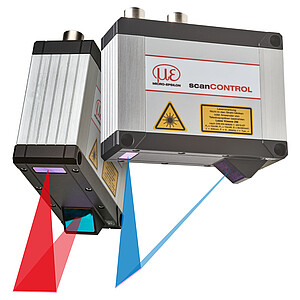

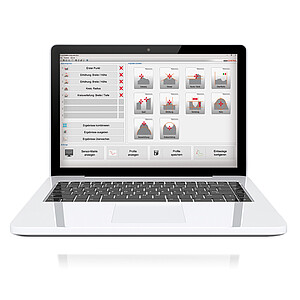

The system TGI 8302.LLT uses three profile sensors which reliable detect bulges and constrictions as well as radial and axial unbalance. The sensors are integrated in a robust mechanics and applied in such a way that the total surface of the tire can be detected within one rotation. Thereby, the tester visualises the tire surface, hides the tire lettering, enables filtering of data, performs a vibration check, inspects the tire size and classifies the degree of a defect.

Special features:

- Resolution: 640 points per profile, 2,000 profile/s

- Reproducibility 40µm (3-sigma)

- Cycle time: 1s/60 R/min