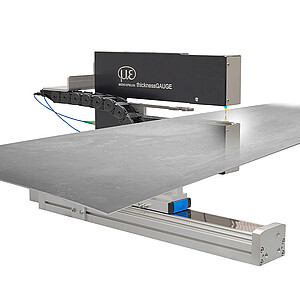

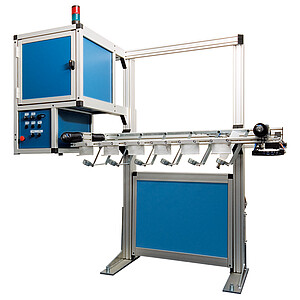

System for precise material distinction

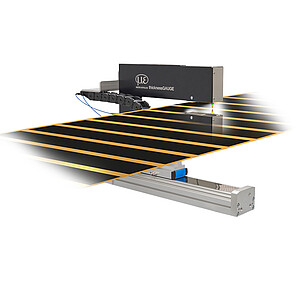

In industrial production, such as nut manufacture, not only the basic colors of products but also materials and coatings must be identified and differentiated. Changes in surface structure, reflection, and/or coloration can cause a different color perception, such as with pressed metal parts and their finishing or coating. In the nut manufacturing process, a distinction must be made between zinc, stainless steel, and brass.

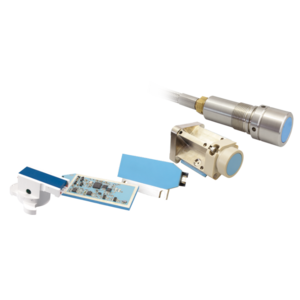

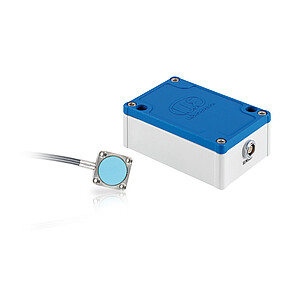

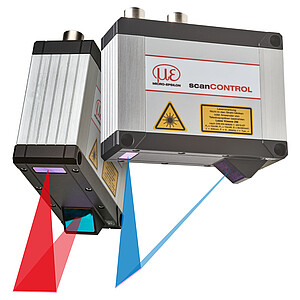

Micro-Epsilon’s colorSENSOR CFO color sensors are intended for these precise color comparison measurements because they reliably detect different materials and enable 100% quality control thanks to the integrated multi-teach function. For this measurement task, the controller is used together with the CFS4-A11 reflex sensor. First, one-time calibration is performed with the sensors on the brightest target, in this case, a zinc nut.

Micro-Epsilon’s colorSENSOR CFO100 and CFO200 color sensors impress with their high color precision and repeatability. The integrated multi-teach function enables correct color identification even with strongly fluctuating color shading between the individual end faces since the color shades can be stored in the CFO and assigned to the corresponding color group. Up to 320 colors can be taught in 254 color groups. With the use of the colorSENSOR CFO, extremely high detection performance rates and process reliability are achieved.

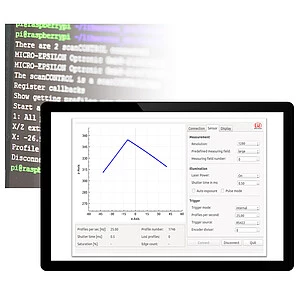

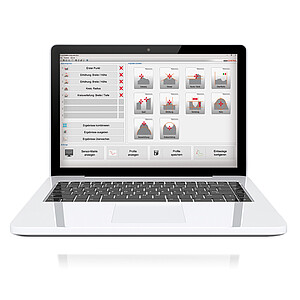

Operation is intuitive via the web interface. The attractive sensor system for precise material distinction consists of the CFO100 controller and the CFS4-A11 sensor and impresses with its excellent price/performance ratio at an attractive price.

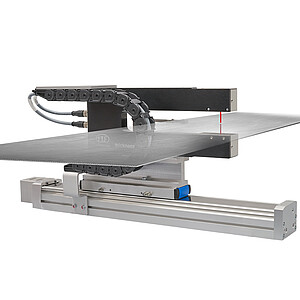

System design

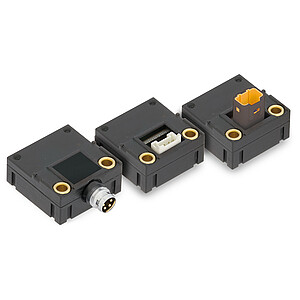

- Controller: colorSENSOR CFO100

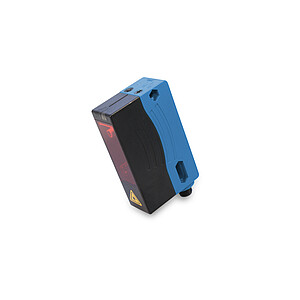

- Reflex sensor: CFS4-A11

Advantages

- Multi-teach function and storage in color groups

- Modern, user-friendly web interface

- High color accuracy and repeatability

- Currently brightest illumination in this class