- 位移感測器

- 渦電流位移計

- Configurator

- eddyNCDT 3001 入門型

![eddyNCDT 3001 入門型 渦電流位移計]() Compact eddy current sensors with integrated controller

Compact eddy current sensors with integrated controller - eddyNCDT 3005 通用型

![eddyNCDT 3005 通用型 渦電流位移計]() Miniature sensor system for integration into machines and systems

Miniature sensor system for integration into machines and systems - eddyNCDT 3020

![eddyNCDT 3020 渦電流位移計]() 適用高環境溫度的感測器系統

適用高環境溫度的感測器系統 - eddyNCDT 3060/3070 高階型

![eddyNCDT 3060/3070 高階型 渦電流位移計]() High-performance sensor system for industrial applications

High-performance sensor system for industrial applications - eddyNCDT 3300 超高速型

![eddyNCDT 3300 超高速型 渦電流位移計]() Ideal für schnelle Messaufgaben

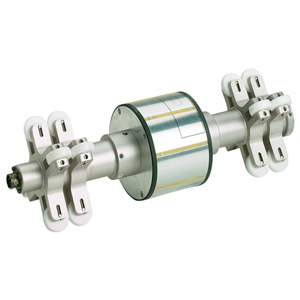

Ideal für schnelle Messaufgaben - SGS 4701 主軸伸長量感測器

![SGS 4701 主軸伸長量感測器 渦電流位移計]()

- 客製化感測器

![客製化感測器 渦電流位移計]()

- 電容式位移計

- Sensor configurator

- capaNCDT 6110 入門型

![capaNCDT 6110 入門型 電容式位移計]() Ideal for industrial applications

Ideal for industrial applications - capaNCDT 61x0/IP 工業型

![capaNCDT 61x0/IP 工業型 電容式位移計]() Robust design for industrial applications

Robust design for industrial applications - capaNCDT 61x4 工業拖鏈型

![capaNCDT 61x4 工業拖鏈型 電容式位移計]() Active measuring system for long cables

Active measuring system for long cables - capaNCDT 6200 模組通用型

![capaNCDT 6200 模組通用型 電容式位移計]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT 6228 耐高溫型

![capaNCDT 6228 耐高溫型 電容式位移計]() Ideal for high-temperature applications

Ideal for high-temperature applications - capaNCDT 6500 高階型

![capaNCDT 6500 高階型 電容式位移計]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT 感測探頭

![capaNCDT 感測探頭 電容式位移計]()

- 客製化感測器

![客製化感測器 電容式位移計]()

- combiSENSOR 塗層測厚型

![combiSENSOR 塗層測厚型 電容式位移計]()

- capaNCDT DTV 碟盤測厚型

![capaNCDT DTV 碟盤測厚型 電容式位移計]()

- capaNCDT MD6-22 手持型

![capaNCDT MD6-22 手持型 電容式位移計]()

- capaNCDT TFG6220

![capaNCDT TFG6220 電容式位移計]() 導電薄膜的厚度量測

導電薄膜的厚度量測

- 雷射感測器

- Configurator

- optoNCDT 1220 入門型

![optoNCDT 1220 入門型 雷射感測器]() Optimized for OEM and series use

Optimized for OEM and series use - optoNCDT 1320 入門高速型

![optoNCDT 1320 入門高速型 雷射感測器]() Compact design for precise measurements

Compact design for precise measurements - optoNCDT 1420 中階型

![optoNCDT 1420 中階型 雷射感測器]() Smart laser sensor for precise measurements

Smart laser sensor for precise measurements - optoNCDT 1900 高階型

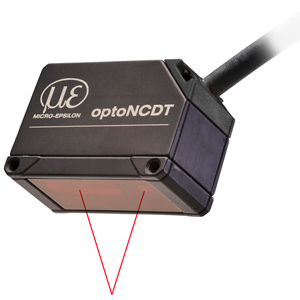

![optoNCDT 1900 高階型 雷射感測器]() Innovative laser sensor for Advanced Automation

Innovative laser sensor for Advanced Automation - optoNCDT 2300 高階型

![optoNCDT 2300 高階型 雷射感測器]() Highly dynamic laser sensor for precise measurements

Highly dynamic laser sensor for precise measurements - optoNCDT 5500 旗艦型

![optoNCDT 5500 旗艦型 雷射感測器]() High-performance laser sensor for high-end applications

High-performance laser sensor for high-end applications - 藍光雷射位移計 BL系列

![藍光雷射位移計 BL系列 雷射感測器]() Blue Laser sensor for metals and organic materials

Blue Laser sensor for metals and organic materials - 寬光點雷射位移計 LL系列

![寬光點雷射位移計 LL系列 雷射感測器]() Ideal for shiny metallic and textured surfaces

Ideal for shiny metallic and textured surfaces - 長距離雷射位移計

![長距離雷射位移計 雷射感測器]() Ideal for large measurement distances

Ideal for large measurement distances - 客製化位移計

![客製化位移計 雷射感測器]()

- 厚度量測專用三角雷射系統

![厚度量測專用三角雷射系統 雷射感測器]()

- 彩色共焦位移計

- Configurator

- 高溫感測器

![高溫感測器 彩色共焦位移計]() 適用於高達 200° C

適用於高達 200° C - 彩色共焦 感測器探頭

![彩色共焦 感測器探頭 彩色共焦位移計]()

- confocalDT IFD2411 新世代分離式彩色共焦

![confocalDT IFD2411 新世代分離式彩色共焦 彩色共焦位移計]() Compact controller for series applications

Compact controller for series applications - confocalDT IFD2410/2415 新世代整合型彩色共焦

![confocalDT IFD2410/2415 新世代整合型彩色共焦 彩色共焦位移計]() 精巧的探頭外型與整合式控制器

精巧的探頭外型與整合式控制器 - 彩色共焦DT IFC2411/IFC2412

![彩色共焦DT IFC2411/IFC2412 彩色共焦位移計]() 用於各式工業應用的精巧型單通道控制器

用於各式工業應用的精巧型單通道控制器 - confocalDT IFC2416/IFC2417 新世代彩色共焦感測器

![confocalDT IFC2416/IFC2417 新世代彩色共焦感測器 彩色共焦位移計]() 用於各式工業應用的精巧型單通道控制器

用於各式工業應用的精巧型單通道控制器 - confocalDT IFC2421/22 通用型控制器

![confocalDT IFC2421/22 通用型控制器 彩色共焦位移計]() Single or dual-channel controller for industrial applications

Single or dual-channel controller for industrial applications - confocalDT IFC2465/66 高速強光源控制器

![confocalDT IFC2465/66 高速強光源控制器 彩色共焦位移計]() One / two-channel controller for fast & precise measurements

One / two-channel controller for fast & precise measurements - Accessoires

![Accessoires 彩色共焦位移計]()

- 白光干涉位移厚度感測器

- interferoMETER 5200-TH 超高精度白光干涉感測器

![interferoMETER 5200-TH 超高精度白光干涉感測器 白光干涉位移厚度感測器]() 可靠的薄層線上測量

可靠的薄層線上測量 - interferoMETER 5400-DS 白光干涉位移計

![interferoMETER 5400-DS 白光干涉位移計 白光干涉位移厚度感測器]() 纳米级精度的绝对距离测量

纳米级精度的绝对距离测量 - interferoMETER 5400-TH 干涉式厚度量測

![interferoMETER 5400-TH 干涉式厚度量測 白光干涉位移厚度感測器]() 稳定的厚度测量,精度达到亚微米级

稳定的厚度测量,精度达到亚微米级 - interferoMETER 5600-DS 超高精度干涉式位移計

![interferoMETER 5600-DS 超高精度干涉式位移計 白光干涉位移厚度感測器]() 亚纳米精度的绝对距离测量

亚纳米精度的绝对距离测量 - interferoMETER 5420-TH

![interferoMETER 5420-TH 白光干涉位移厚度感測器]() SI 晶片的高精度厚度测量

SI 晶片的高精度厚度测量

- interferoMETER 5200-TH 超高精度白光干涉感測器

- 雷射長距離感測器

- optoNCDT ILR1171 超長距離 室外專用

![optoNCDT ILR1171 超長距離 室外專用 雷射長距離感測器]() High speed sensors also for outdoor applications

High speed sensors also for outdoor applications - optoNCDT ILR3800 全新通用型

![optoNCDT ILR3800 全新通用型 雷射長距離感測器]() 適用於工業應用的高性能雷射距離感測器

適用於工業應用的高性能雷射距離感測器 - optoNCDT ILR104x 經濟型

![optoNCDT ILR104x 經濟型 雷射長距離感測器]() 輕巧可靠的長距離雷射感測器

輕巧可靠的長距離雷射感測器

- optoNCDT ILR1171 超長距離 室外專用

- LVDT 感應式位移計

- induSENSOR DTD gauge

![induSENSOR DTD gauge LVDT 感應式位移計]() Push-button with compact cable controller

Push-button with compact cable controller - induSENSOR DTA gauge

![induSENSOR DTA gauge LVDT 感應式位移計]() LVDT gauges

LVDT gauges - induSENSOR DTA sensors

![induSENSOR DTA sensors LVDT 感應式位移計]() LVDT 感應式位移計

LVDT 感應式位移計 - induSENSOR LDR

![induSENSOR LDR LVDT 感應式位移計]() Linear displacement sensors

Linear displacement sensors - Clamping stroke sensor

![Clamping stroke sensor LVDT 感應式位移計]() Sensors for monitoring the clamping position

Sensors for monitoring the clamping position - MSC7x0x controller

![MSC7x0x controller LVDT 感應式位移計]()

- induSENSOR EDS

![induSENSOR EDS LVDT 感應式位移計]() Long-stroke sensors with integrated electronics

Long-stroke sensors with integrated electronics - Inductive sensors for specific applications

![Inductive sensors for specific applications LVDT 感應式位移計]()

- induSENSOR DTD gauge

- 磁感應式位移計

- mainSENSOR MDS-35/-45

![mainSENSOR MDS-35/-45 磁感應式位移計]() 採用 M12、M18 和 M30 設計的堅固型感測器

採用 M12、M18 和 M30 設計的堅固型感測器 - mainSENSOR MDS-40-MK

![mainSENSOR MDS-40-MK 磁感應式位移計]() Sensors for series applications

Sensors for series applications - mainSENSOR MDS-40-LP

![mainSENSOR MDS-40-LP 磁感應式位移計]() Sensors with circuit-board design

Sensors with circuit-board design - Customer-specific sensors

![Customer-specific sensors 磁感應式位移計]()

- mainSENSOR MDS-35/-45

- 拉線式位移計

- 適用於串列整合與 OEM 的拉線式感測器

![適用於串列整合與 OEM 的拉線式感測器 拉線式位移計]() 具有塑膠外殼的微型感測器

具有塑膠外殼的微型感測器 - 工業用拉線式感測器

![工業用拉線式感測器 拉線式位移計]() 鋁製外殼的堅固感測器

鋁製外殼的堅固感測器 - 工業用拉線式位移感測器

![工業用拉線式位移感測器 拉線式位移計]() 適用於高線加速度

適用於高線加速度 - 機構

![機構 拉線式位移計]() 用於安裝編碼器的拉線機構

用於安裝編碼器的拉線機構

- 適用於串列整合與 OEM 的拉線式感測器

- 渦電流位移計

- 工業感測器

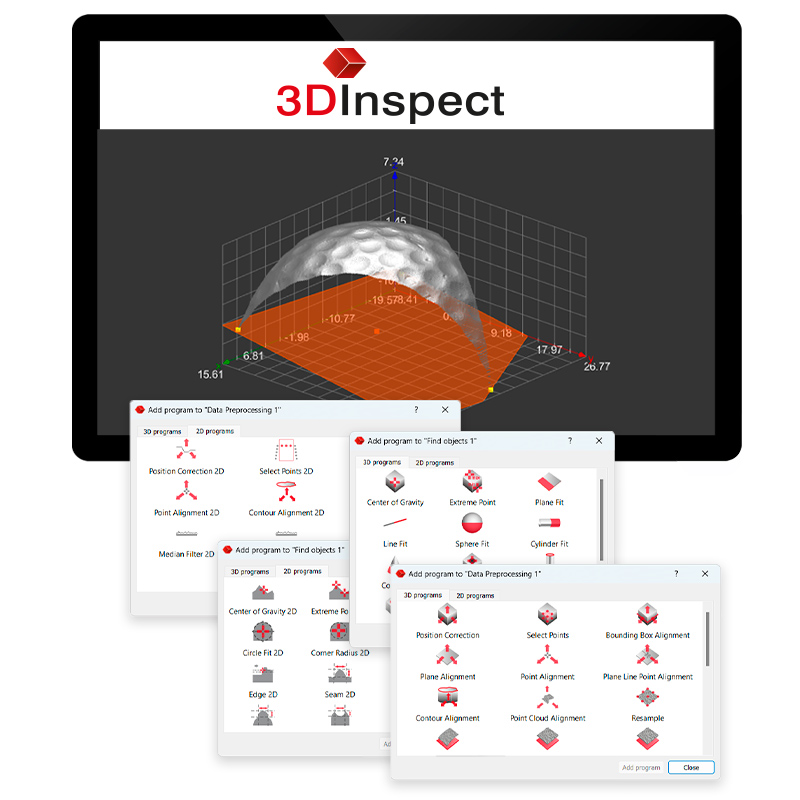

- 2D/3D 量測

- 3D 感測器

- 高解析度光學測微計

- optoCONTROL 1200 入門型

![optoCONTROL 1200 入門型 高解析度光學測微計]() Compact high-speed micrometer

Compact high-speed micrometer - optoCONTROL 2520 通用型

![optoCONTROL 2520 通用型 高解析度光學測微計]() Compact laser micrometer (class 1M)

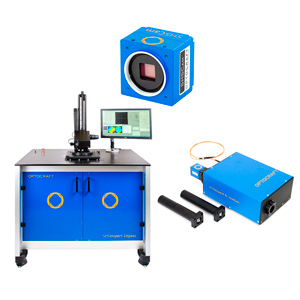

Compact laser micrometer (class 1M) - optoCONTROL 2700

![optoCONTROL 2700 高解析度光學測微計]() 滿足最高要求的高性能測微計

滿足最高要求的高性能測微計

- optoCONTROL 1200 入門型

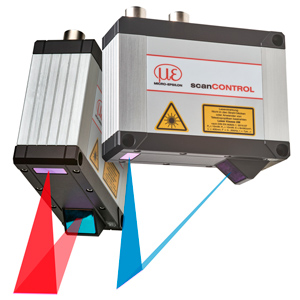

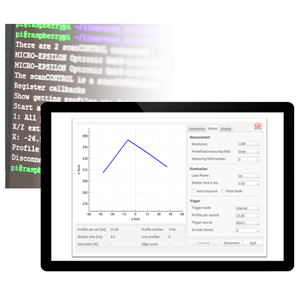

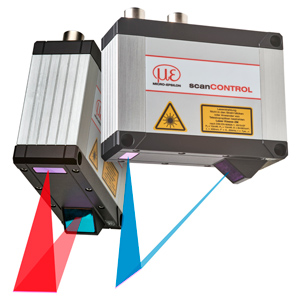

- 線雷射輪廓儀

- Configurator

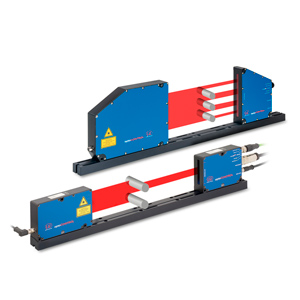

- scanCONTROL 25x0 入門經濟型

![scanCONTROL 25x0 入門經濟型 線雷射輪廓儀]() Laser scanner for series applications

Laser scanner for series applications - scanCONTROL 29x0 中階型

![scanCONTROL 29x0 中階型 線雷射輪廓儀]() Compact laser scanners with high precision

Compact laser scanners with high precision - scanCONTROL 30x2 通用經濟型

![scanCONTROL 30x2 通用經濟型 線雷射輪廓儀]() Powerful 2D/3D laser scanners

Powerful 2D/3D laser scanners - scanCONTROL 30x0 高階型

![scanCONTROL 30x0 高階型 線雷射輪廓儀]() High-performance laser scanners

High-performance laser scanners - 軟體

- 選項與配件

![選項與配件 線雷射輪廓儀]()

- 應用

![應用 線雷射輪廓儀]()

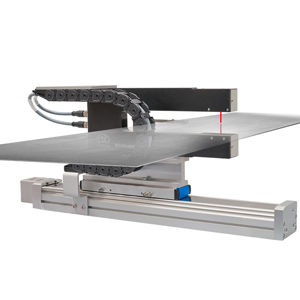

- 線上量測系統

- 高精度線上厚度量測系統模組

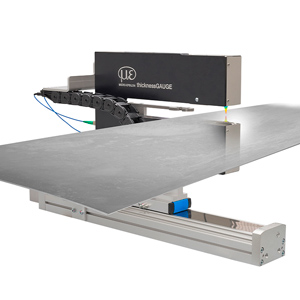

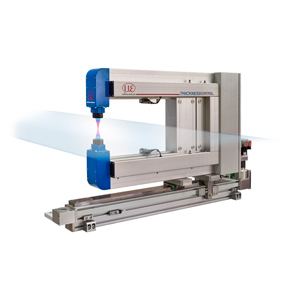

- thicknessGAUGE 3D

![thicknessGAUGE 3D 高精度線上厚度量測系統模組]() Inline thickness and profile measurements

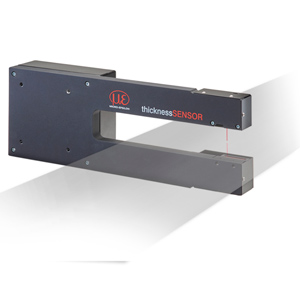

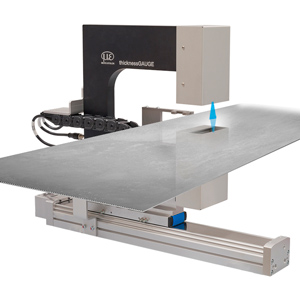

Inline thickness and profile measurements - thicknessGAUGE C.LL

![thicknessGAUGE C.LL 高精度線上厚度量測系統模組]() Inline thickness measurement (laser sensors)

Inline thickness measurement (laser sensors) - thicknessGAUGE C.C

![thicknessGAUGE C.C 高精度線上厚度量測系統模組]() Inline thickness measurement (confocal)

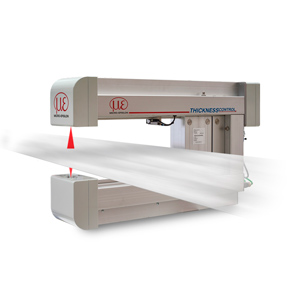

Inline thickness measurement (confocal) - thicknessGAUGE C.LP

![thicknessGAUGE C.LP 高精度線上厚度量測系統模組]() Inline-Dickenmessung (Laser-Profilsensoren)

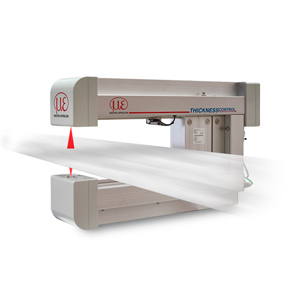

Inline-Dickenmessung (Laser-Profilsensoren) - thicknessGAUGE O.EC

![thicknessGAUGE O.EC 高精度線上厚度量測系統模組]() Inline thickness measurement (eddy current/capacitive)

Inline thickness measurement (eddy current/capacitive)

- thicknessGAUGE 3D

- 鋼鐵製程專用線上量測設備

- 汽車產業用線上量測設備

- 電池製程線上量測設備

- Inspection and production systems for the tire industry

- 塑膠薄膜專用線上量測設備

- 高精度線上厚度量測系統模組

- OEM

- 產品應用

- 聯絡我們