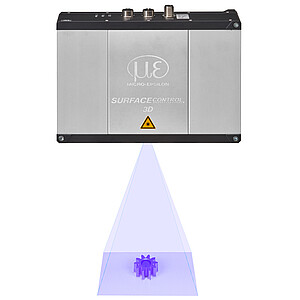

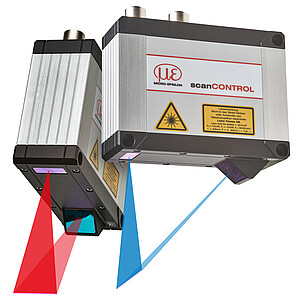

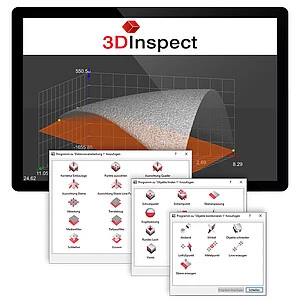

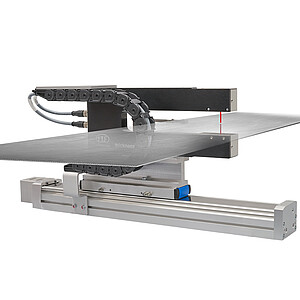

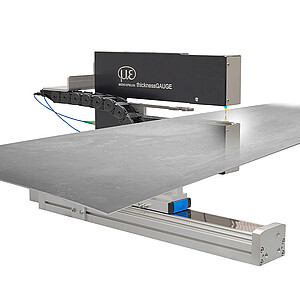

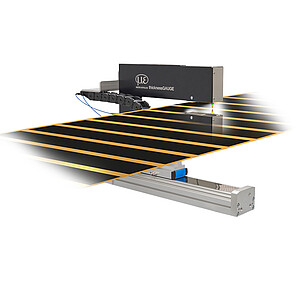

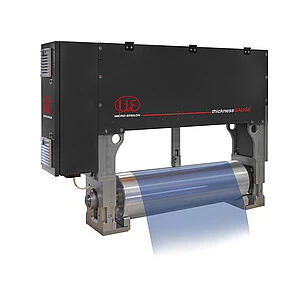

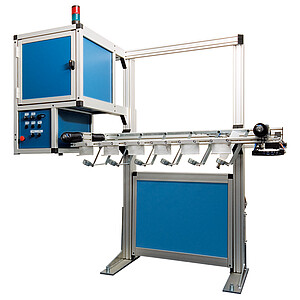

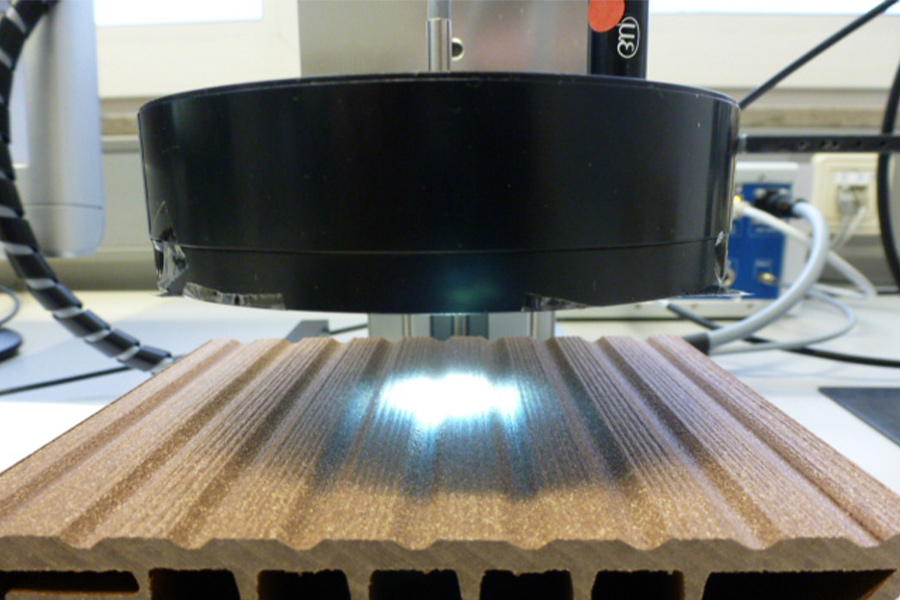

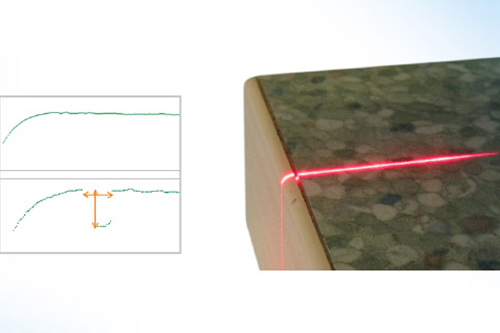

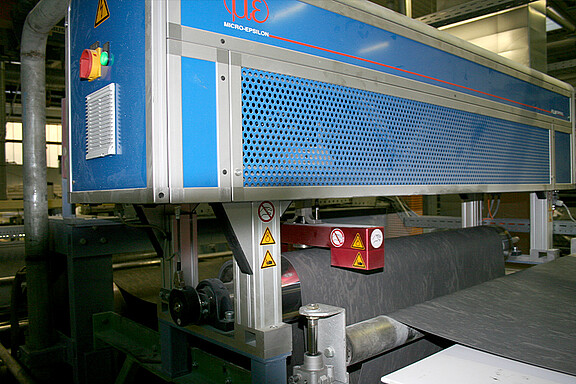

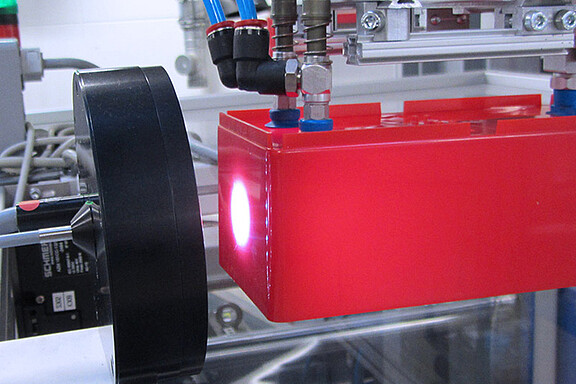

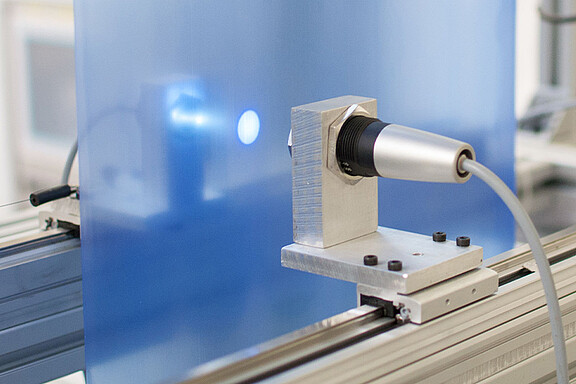

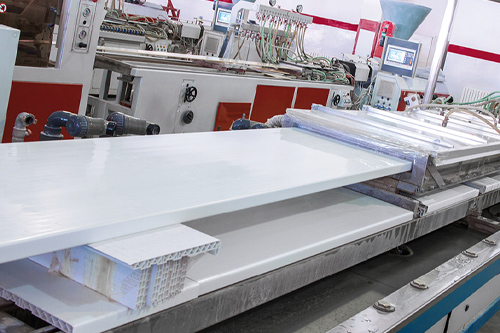

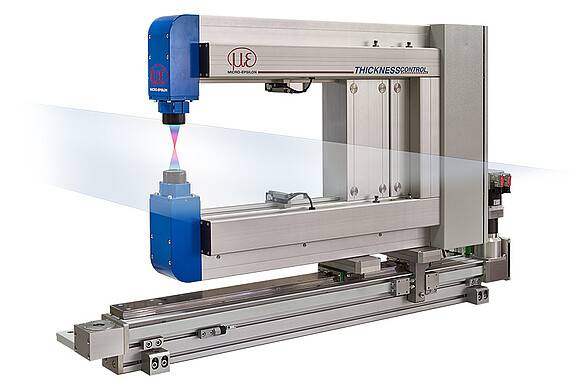

Plastics production and processing

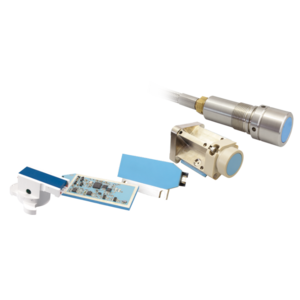

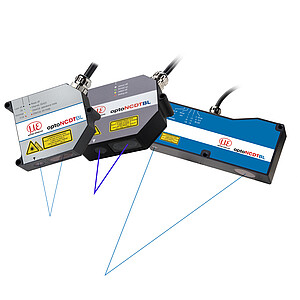

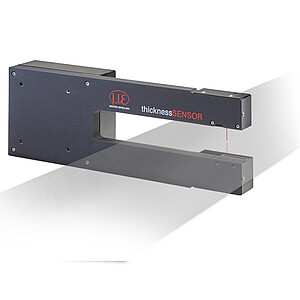

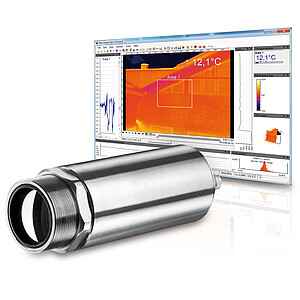

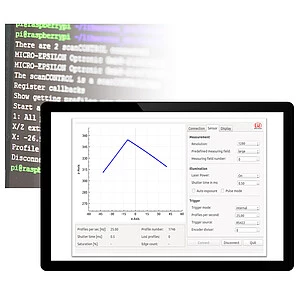

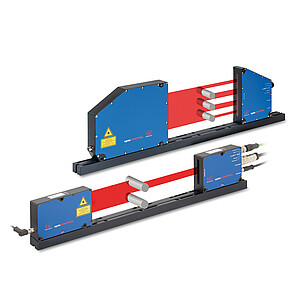

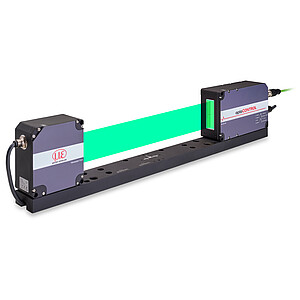

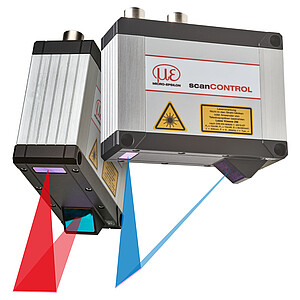

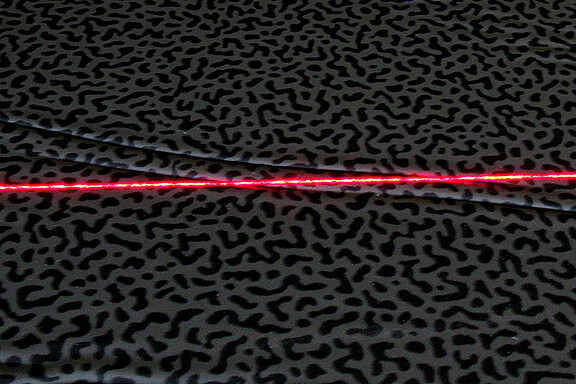

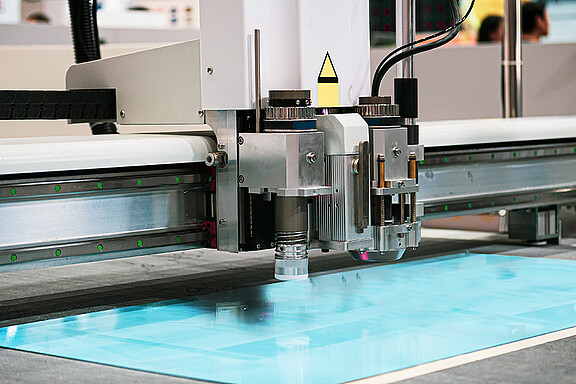

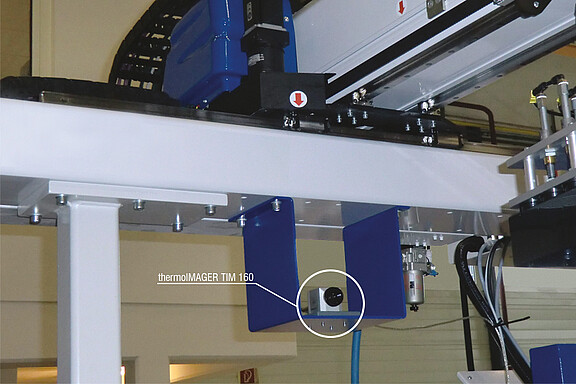

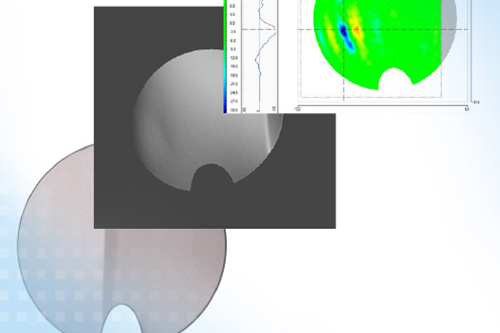

Micro-Epsilon offers a wide range of sensors and solutions for non-contact measurement of plastics production. Dimensions, thickness, temperature, colors and embossing patterns in roll or sheet form can be reliably measured in a wide range of process steps from extrusion via molding to further processing.